The Remarkable Properties of 3mm Titanium Plates

Unmatched Biocompatibility and Safety

One of the most crucial aspects of any medical implant is its biocompatibility. 3mm titanium plates excel in this area, offering seamless integration with human tissue. The human body readily accepts titanium, reducing the risk of rejection or adverse reactions. This remarkable biocompatibility is due to titanium's ability to form a stable oxide layer on its surface, which acts as a protective barrier between the implant and surrounding tissues.

Furthermore, the use of high-grade titanium alloys such as Ti6Al4V and Ti6Al4V ELI ensures that these plates meet the stringent safety standards required for medical implants. These materials have undergone rigorous testing and have proven their safety in numerous clinical applications.

Lightweight Design for Patient Comfort

Despite their impressive strength, 3mm titanium plates are incredibly lightweight. This characteristic is paramount in minimizing patient discomfort, especially in cases where multiple plates or extensive implantation is necessary. The low density of titanium, combined with the thin 3mm profile, results in plates that are barely noticeable to the patient once implanted.

This lightweight nature doesn't compromise the structural integrity of the plates. In fact, titanium boasts an exceptional strength-to-weight ratio, allowing these thin plates to provide robust support where needed. This balance between strength and weight makes 3mm titanium plates an ideal choice for a wide range of medical applications, from facial reconstruction to orthopedic surgeries.

Superior Corrosion Resistance

The human body can be a harsh environment for implants, with various bodily fluids and chemicals potentially causing degradation over time. However, 3mm titanium plates exhibit excellent corrosion resistance, making them suitable for long-term medical use. This resistance stems from the aforementioned oxide layer that forms on the titanium surface, protecting the underlying metal from corrosive elements.

The corrosion resistance of these plates ensures their longevity and maintains their structural integrity over extended periods. This property is particularly crucial in implants that are expected to remain in the body for many years or even a lifetime. Patients can have confidence in the durability of their titanium implants, knowing that they will continue to function effectively without degradation.

Applications and Advantages of 3mm Titanium Plates in Medical Settings

Versatility in Surgical Applications

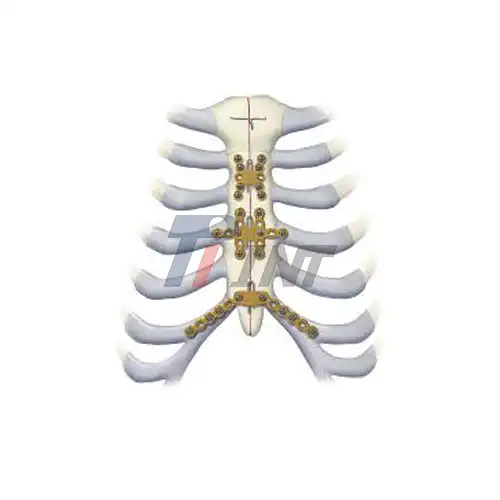

The versatility of 3mm titanium plates makes them indispensable in various surgical fields. In orthopedics, these plates are commonly used for fracture fixation, providing stable support for bone healing. Their thin profile allows for minimally invasive procedures, reducing surgical trauma and promoting faster recovery.

In maxillofacial surgery, 3mm titanium plates play a crucial role in facial reconstruction. Their malleability allows surgeons to contour the plates to match the patient's unique facial anatomy, ensuring both functional and aesthetic outcomes. The plates' strength supports the facial structure while remaining discreet beneath the skin.

Neurosurgery also benefits from the use of 3mm titanium plates. In cranial procedures, these plates are used to secure bone flaps after surgery, providing protection for the brain while allowing for optimal healing. The plates' low profile minimizes their visibility under the scalp, contributing to improved cosmetic results.

High Strength and Flexibility

Despite their thin 3mm profile, titanium plates offer remarkable strength. This high strength allows them to withstand significant forces, making them suitable for load-bearing applications in orthopedic surgeries. The plates provide stable fixation for fractured bones, allowing for proper alignment during the healing process.

Simultaneously, these plates exhibit a degree of flexibility that is crucial in many medical applications. This flexibility allows the plates to conform to the natural contours of bones and joints, ensuring a better fit and reducing the risk of implant failure due to rigid stress points. The balance between strength and flexibility contributes to the overall effectiveness and longevity of the implant.

Exceptional Fatigue Resistance

In many medical applications, implants are subjected to repetitive stress over extended periods. This is where the fatigue resistance of 3mm titanium plates becomes invaluable. Titanium and its alloys have superior fatigue properties compared to many other implant materials, allowing them to withstand cyclic loading without failure.

This exceptional fatigue resistance ensures the long-term performance of the implant, particularly in areas of the body that experience constant movement or stress. For instance, in spinal surgeries, titanium plates used for vertebral fusion must withstand the continuous movements of the spine. The fatigue resistance of these plates provides patients with the assurance that their implants will remain stable and functional for years to come.

Quality Assurance and Customization of 3mm Titanium Plates

Rigorous Certification and Quality Control

The production of 3mm titanium plates adheres to stringent quality standards to ensure patient safety and product reliability. Reputable manufacturers, such as Baoji INT Medical Titanium Co., Ltd., hold certifications that attest to their commitment to quality. These certifications typically include ISO9001:2015 for quality management systems and ISO13485:2016 specifically for medical devices.

Additionally, products intended for use in the European market often carry the EU CE marking, indicating compliance with health, safety, and environmental protection standards. These certifications involve regular audits and inspections, ensuring that the manufacturing processes consistently meet the highest quality standards.

Quality control measures extend throughout the production process, from raw material selection to final product testing. Each 3mm titanium plate undergoes rigorous inspection to verify its dimensional accuracy, surface finish, and mechanical properties. This meticulous attention to detail ensures that every plate meets the exacting standards required for medical implants.

Customization Options for Surgical Precision

While standardized 3mm titanium plates are suitable for many applications, the ability to customize these plates is a significant advantage in complex surgical cases. Leading manufacturers offer customization services to meet specific surgical needs, allowing for the creation of bespoke implants tailored to individual patient anatomies.

Customization options may include alterations in plate shape, hole placement, or curvature to accommodate unique anatomical requirements. This level of customization is particularly valuable in reconstructive surgeries, where standard plates may not provide the optimal fit or function.

Advanced manufacturing techniques, such as 3D printing and computer-aided design (CAD), have further expanded the possibilities for customization. These technologies allow for the rapid prototyping and production of complex, patient-specific implants, pushing the boundaries of what's possible in personalized medical care.

Durability and Long-Term Performance

The exceptional durability of 3mm titanium plates is a testament to the material's inherent properties and the quality of manufacturing processes. Titanium's resistance to wear and corrosion ensures that these plates maintain their structural integrity and functionality over extended periods, even in the challenging environment of the human body.

Long-term studies have demonstrated the excellent performance of titanium implants, with many patients experiencing decades of trouble-free use. This durability not only improves patient outcomes but also reduces the need for revision surgeries, which can be both costly and risky.

The combination of titanium's material properties and the precise engineering of 3mm plates results in implants that can withstand the rigors of daily use while maintaining their biocompatibility. This long-term stability provides peace of mind for both surgeons and patients, knowing that the implant will continue to perform its intended function reliably over time.

Conclusion

3mm titanium plates represent a pinnacle of medical implant technology, offering an unparalleled combination of strength, lightness, and reliability. Their biocompatibility, corrosion resistance, and fatigue resistance make them ideal for a wide range of surgical applications, from orthopedics to neurosurgery. The ability to customize these plates further enhances their utility in complex cases, allowing for truly personalized patient care.

As medical technology continues to advance, 3mm titanium plates remain at the forefront of implant solutions, providing surgeons with reliable tools to improve patient outcomes and quality of life. For those seeking high-quality medical titanium products, including 3mm titanium plates, Baoji INT Medical Titanium Co., Ltd. offers a comprehensive range of options backed by years of expertise in the field. To learn more about their products and services, interested parties can reach out via email at export@tiint.com.

2025-08-27 13:32:47

2025-08-27 13:32:47

_1752821449466.webp)

_1752818317695.webp)

_1750662961697.webp)