The Unique Properties of Medical Titanium Plates

Biocompatibility: A Harmonious Relationship with Human Tissue

One of the most momentous highlights of therapeutic titanium plates is their uncommon biocompatibility. This property guarantees that the plates coordinated consistently with human tissue, minimizing the chance of unfavorable responses or dismissal. The human body's acknowledgment of titanium stems from its capacity to frame a steady oxide layer on its surface, which acts as a defensive obstruction against erosion and avoids the discharge of possibly hurtful particles.

This biocompatibility is crucial in medical applications, as it allows for long-term implantation without compromising the patient's health or the functionality of the implant. Surgeons can confidently use medical titanium plates knowing that they will not trigger immune responses or cause inflammation, which could otherwise lead to complications or implant failure.

Strength and Durability: Supporting Recovery

Therapeutic titanium plates brag an amazing strength-to-weight proportion, making them both strong and lightweight. This special combination permits for the creation of inserts that can withstand noteworthy push whereas remaining simple for specialists to handle and control amid methods. The solidness of titanium guarantees that these plates keep up their auxiliary astuteness over time, indeed when subjected to the steady development and powers inside the human body.

The strength of medical titanium plates is particularly beneficial in load-bearing applications, such as in orthopedic surgeries involving the spine or long bones. These implants can provide the necessary support for proper healing and alignment without adding excessive weight or bulk to the surgical site.

Corrosion Resistance: Longevity in Challenging Environments

The human body presents a challenging environment for implants, with varying pH levels and constant exposure to bodily fluids. Medical titanium plates excel in this setting due to their outstanding corrosion resistance. The aforementioned oxide layer that forms on the surface of titanium acts as a protective shield, preventing degradation of the implant over time.

This resistance to corrosion is vital for several reasons. It ensures the longevity of the implant, reducing the need for revision surgeries and minimizing patient discomfort. Additionally, it prevents the release of metal ions into the surrounding tissues, which could potentially lead to adverse reactions or systemic health issues.

Customizability: Tailored Solutions for Individual Needs

The versatility of medical titanium plates extends to their customizability. Manufacturers can produce plates in a wide range of sizes, shapes, and thicknesses to meet specific surgical requirements. This flexibility allows surgeons to select or even design implants that perfectly fit the patient's anatomy and address their unique medical needs.

Customization options include varying the thickness from as thin as 0.5mm to as thick as 100mm, with widths up to 1000mm. The length of the plates can be tailored to the exact specifications required for each procedure. This level of customization ensures optimal fit and function, potentially improving surgical outcomes and patient comfort.

Applications of Medical Titanium Plates in Modern Healthcare

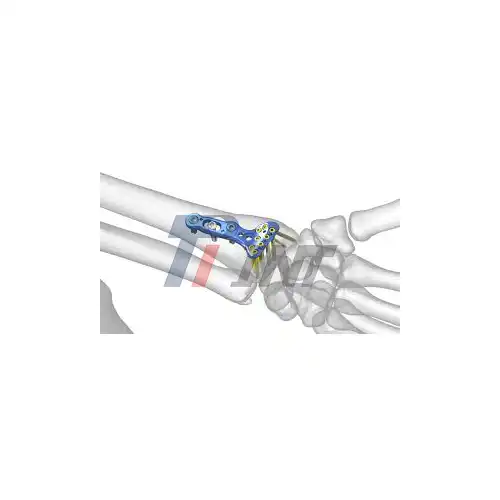

Orthopedic Surgery: Restoring Skeletal Integrity

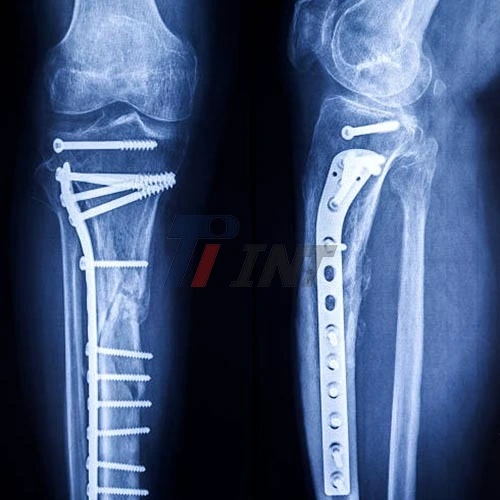

Medical titanium plates find extensive use in orthopedic surgery, where they play a crucial role in fracture fixation and bone reconstruction. These plates are instrumental in treating complex fractures, particularly in weight-bearing bones such as the femur, tibia, and humerus. By providing stable fixation, they allow for proper alignment of bone fragments and promote optimal healing conditions.

In spinal surgery, titanium plates are used to stabilize the vertebrae following procedures such as discectomies or spinal fusion. The plates help maintain the correct spinal alignment and provide the necessary support during the healing process, ultimately improving patient mobility and quality of life.

Craniofacial and Maxillofacial Surgery: Reconstructing and Enhancing

The adaptability of medical titanium plates makes them invaluable in craniofacial and maxillofacial surgeries. These procedures often require precise reconstruction of complex facial structures. Titanium plates can be shaped and contoured to match the natural curvatures of the skull and facial bones, allowing surgeons to restore both function and aesthetics.

In cases of facial trauma, congenital deformities, or post-cancer reconstruction, medical titanium plates provide the structural support necessary to rebuild and reshape facial features. Their biocompatibility is particularly beneficial in these sensitive areas, where rejection or inflammation could have significant consequences for the patient's appearance and well-being.

Dental Implantology: Foundations for Dental Restoration

While not plates in the traditional sense, titanium is also extensively used in dental implants, which serve as artificial tooth roots. These implants integrate with the jawbone through a process called osseointegration, providing a stable foundation for dental prosthetics. The principles that make titanium plates successful in other medical applications—biocompatibility, strength, and corrosion resistance—are equally valuable in dental implantology.

The use of titanium in dental applications has revolutionized the field, offering long-lasting solutions for tooth replacement that closely mimic natural teeth in both function and appearance. This application showcases the versatility of titanium across various medical disciplines.

Advantages of Medical Titanium Plates in Surgical Procedures

Enhanced Patient Outcomes: Faster Recovery and Reduced Complications

The use of medical titanium plates often translates to improved patient outcomes. The biocompatibility of titanium reduces the risk of post-operative complications such as infections or implant rejection. This can lead to faster recovery times and shorter hospital stays, benefiting both patients and healthcare providers.

Moreover, the strength and stability provided by titanium plates can allow for earlier mobilization of patients following surgery. This is particularly important in orthopedic cases, where early movement can prevent complications associated with prolonged immobility and contribute to faster rehabilitation.

Imaging Compatibility: Facilitating Post-Operative Monitoring

Not at all like a few other metals utilized in restorative inserts, titanium is consistent with different imaging advances, including MRI and CT filters. This compatibility is vital for post-operative checking and long-term follow-up. Specialists can precisely survey the mending handle and the position of the embed without the impedances that might happen with other materials.

This imaging-friendly nature of titanium also aids in the early detection of any potential complications, allowing for prompt intervention if necessary. It provides healthcare providers with valuable insights into the patient's recovery without the need for invasive procedures.

Long-Term Cost-Effectiveness: Durability Translates to Savings

While the initial cost of medical titanium plates may be higher compared to some alternatives, their longevity and reduced complication rates often make them more cost-effective in the long run. The durability of titanium implants means they are less likely to require replacement or revision surgeries, saving patients from additional procedures and associated costs.

Furthermore, the reduced risk of complications and faster recovery times can lead to shorter hospital stays and fewer follow-up visits, contributing to overall cost savings in patient care. This long-term economic benefit aligns with the growing focus on value-based healthcare.

Versatility in Manufacturing: Meeting Diverse Surgical Needs

The manufacturing process for medical titanium plates offers a high degree of versatility. Plates can be produced using various methods, including machining, forging, and 3D printing. This flexibility allows for the creation of complex geometries and patient-specific designs that may not be possible with other materials.

Additionally, the surface of titanium plates can be modified to enhance their performance. Treatments such as polishing or acid-cleaning can optimize the surface properties for specific applications, further improving biocompatibility and integration with surrounding tissues.

Quality Assurance: Meeting Rigorous Industry Standards

Medical titanium plates are subject to stringent quality control measures and industry certifications. Reputable manufacturers adhere to standards such as ISO9001:2015 for quality management systems and ISO13485:2016 specifically for medical devices. These certifications, along with CE marking for products sold in the European market, ensure that medical titanium plates meet the highest standards of safety and efficacy.

This commitment to quality assurance provides confidence to healthcare providers and patients alike, knowing that the implants used in surgical procedures have undergone rigorous testing and comply with international regulations.

Conclusion

Medical titanium plate has established themselves as essential components in modern surgical practice. Their unique combination of biocompatibility, strength, corrosion resistance, and customizability make them ideal for a wide range of medical applications. As technology advances, we can expect to see further innovations in the design and manufacturing of these implants, potentially expanding their use to even more diverse medical fields.

For healthcare providers and patients seeking high-quality medical titanium products, it's crucial to partner with experienced and reputable manufacturers. Baoji INT Medical Titanium Co., Ltd., with its long-standing expertise in the field, offers a comprehensive range of medical titanium solutions. To learn more about their products and how they can benefit your medical practice or personal health journey, please contact them at export@tiint.com.

2025-07-04 14:06:43

2025-07-04 14:06:43

_1752463076575.webp)

_1751620280646.webp)