The Revolutionary Properties of 3mm Titanium Plates in Surgical Implants

Unparalleled Biocompatibility and Integration

One of the most crucial aspects of any surgical implant is its ability to integrate seamlessly with the human body. 3mm titanium plates excel in this regard, thanks to titanium's exceptional biocompatibility. This property ensures that the implant does not trigger adverse reactions or rejections when introduced into the body. The human body readily accepts titanium, allowing for a smoother recovery process and reducing the risk of complications.

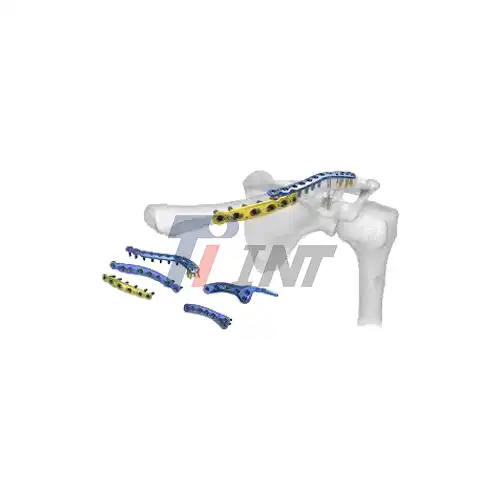

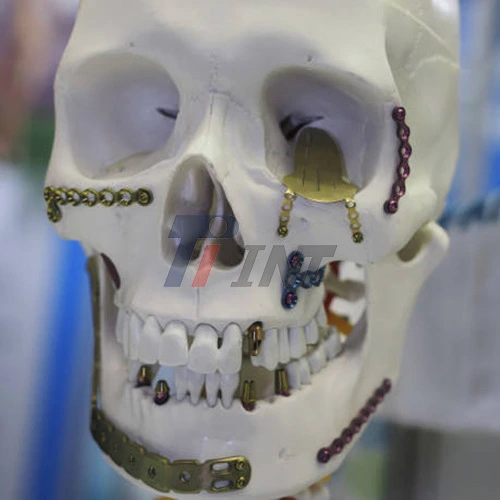

Moreover, titanium's ability to osseointegrate – the process by which bone cells attach directly to the implant surface – makes it an ideal choice for orthopedic and maxillofacial surgeries. This integration promotes faster healing and provides a stable foundation for bone growth, ultimately leading to better long-term outcomes for patients.

Lightweight Design for Enhanced Patient Comfort

Despite their durability, 3mm titanium plates are remarkably lightweight. This characteristic is particularly beneficial in surgeries where minimizing the burden on surrounding tissues is crucial. The reduced weight of titanium implants compared to other materials like stainless steel means less strain on the patient's body, potentially leading to quicker recovery times and improved mobility post-surgery.

The lightweight nature of these plates also contributes to their versatility. Surgeons can use them in delicate areas where heavier implants might cause discomfort or interfere with normal bodily functions. This makes 3mm titanium plates suitable for a wide range of applications, from cranial reconstructions to spinal surgeries.

Superior Corrosion Resistance for Long-term Stability

One of the standout features of 3mm titanium plates is their exceptional resistance to corrosion. This property is crucial for implants that are expected to remain in the body for extended periods, sometimes even for a lifetime. Titanium's natural ability to form a protective oxide layer on its surface provides an additional barrier against corrosive elements present in bodily fluids.

The corrosion resistance of titanium plates ensures that they maintain their structural integrity over time, reducing the risk of implant failure or the need for revision surgeries. This longevity not only improves patient outcomes but also contributes to cost-effectiveness in the long run by minimizing the need for replacements.

Mechanical Prowess: Strength and Durability of 3mm Titanium Plates

High Strength-to-Weight Ratio

The 3mm titanium plate boasts an impressive strength-to-weight ratio, a critical factor in its success as a surgical implant. This property allows the plate to provide robust support and stabilization while remaining thin and lightweight. The high strength of titanium alloys used in these plates enables them to withstand significant forces without deformation, ensuring that they maintain their shape and function even under stress.

This combination of strength and lightness is particularly advantageous in load-bearing applications, such as in spinal fusion surgeries or complex fracture repairs. Surgeons can rely on the 3mm titanium plate to provide the necessary support for proper healing without overburdening the patient with excessive implant weight.

Fatigue Resistance for Long-term Performance

In many surgical applications, implants are subjected to repeated stress cycles over extended periods. This is where the fatigue resistance of 3mm titanium plates becomes crucial. Titanium's inherent ability to withstand cyclic loading without developing cracks or failing makes it an ideal material for implants that need to endure constant movement or pressure.

The high fatigue resistance of these plates ensures that they can maintain their structural integrity even in dynamic environments, such as in joint reconstructions or in areas of the body subject to frequent motion. This property contributes significantly to the long-term success of surgeries and reduces the likelihood of implant-related complications over time.

Flexibility and Adaptability in Surgical Applications

While strength and durability are essential, the ability to adapt to the natural contours of the body is equally important for surgical implants. 3mm titanium plates offer a unique balance of rigidity and flexibility, allowing surgeons to mold them to fit the specific anatomical requirements of each patient. This adaptability is particularly valuable in reconstructive surgeries where precise contouring is necessary for optimal results.

The malleability of titanium enables surgeons to make fine adjustments during the procedure, ensuring a perfect fit without compromising the plate's structural integrity. This flexibility also contributes to better load distribution, reducing stress concentrations that could lead to implant failure or bone resorption.

Quality Assurance and Customization of 3mm Titanium Plates

Rigorous Certification and Quality Control

The production of 3mm titanium plates is subject to stringent quality control measures and international certifications. Reputable manufacturers adhere to standards such as ISO9001:2015 for quality management systems and ISO13485:2016 specifically for medical devices. These certifications guarantee that the plates meet the most elevated benchmarks of quality, consistency, and security required for therapeutic inserts.

Moreover, compliance with EU CE stamping illustrates that the items meet the fundamental necessities of the significant European wellbeing, security, and natural security enactment. This comprehensive quality affirmation handle gives specialists and patients with certainty in the unwavering quality and security of 3mm titanium plates utilized in surgical methods.

Customization Options for Diverse Surgical Needs

Recognizing that every surgical case is unique, many manufacturers offer customization options for 3mm titanium plates. This flexibility allows surgeons to request specific dimensions, shapes, or features that may be required for particular procedures or patient anatomies. Custom titanium plates can be designed to address complex reconstructive challenges or to optimize the fit in specific anatomical regions.

The ability to customize these plates not only improves surgical outcomes but also expands the range of applications for titanium implants. From patient-specific cranial plates to tailored fixation systems for complex fractures, the customization of 3mm titanium plates represents a significant advancement in personalized surgical solutions.

Advanced Manufacturing Techniques

The production of high-quality 3mm titanium plates involves sophisticated manufacturing processes. Techniques such as precision die forging, CNC machining, and advanced surface treatments are employed to ensure the plates meet exacting specifications. These processes contribute to the overall quality, consistency, and performance of the final product.

Some manufacturers utilize cutting-edge technologies like 3D printing or additive manufacturing to create complex geometries or patient-specific implants. These advanced techniques allow for the production of titanium plates with intricate designs that may not be feasible with traditional manufacturing methods, further expanding the possibilities for surgical applications.

Conclusion

The 3mm titanium plate represents a significant advancement in surgical implant technology, offering a combination of durability, biocompatibility, and versatility that is unmatched by many other materials. Its superior properties make it an invaluable tool in a wide range of surgical procedures, from orthopedics to maxillofacial reconstruction. As medical technology continues to evolve, the role of titanium in surgical implants is likely to expand further, driven by ongoing research and development in materials science and manufacturing techniques.

For surgeons and medical professionals seeking high-quality 3mm titanium plates and other medical titanium products, Baoji INT Medical Titanium Co., Ltd. offers a comprehensive range of solutions. With over 30 years of experience in the research, development, and production of titanium materials, INT has established itself as a leader in the medical titanium industry. Their commitment to quality, innovation, and customer satisfaction makes them an ideal partner for healthcare providers looking to improve patient outcomes through advanced implant technologies. For more information or to discuss your specific requirements, please contact INT at export@tiint.com.

2025-10-10 08:47:25

2025-10-10 08:47:25

_1752462890412.webp)

_1750668472070.webp)

_1753926673602.jpg)