The Remarkable Properties of Medical Titanium Plates

Unparalleled Strength-to-Weight Ratio

Therapeutic titanium plates boast an extraordinary strength-to-weight proportion, a characteristic that sets them apart in the domain of surgical inserts. This interesting property permits the creation of strong, lightweight gadgets, vital for quiet consolation and versatility. The inborn quality of titanium empowers these plates to withstand noteworthy push and strain, making them appropriate for load-bearing applications in orthopedic surgeries.

Besides, the lightweight nature of titanium plates minimizes the burden on encompassing tissues, decreasing the chance of complications such as delicate tissue disturbance or bone resorption. This adjustment between quality and weight is especially advantageous in zones where a negligible embed profile is craved, such as craniofacial recreations or spinal surgeries.

Superior Corrosion Resistance

One of the standout features of medical titanium plates is their remarkable resistance to corrosion. In the aggressive environment of the human body, where fluids, enzymes, and various biochemical processes can degrade many materials, titanium remains steadfast. This corrosion resistance is attributed to the formation of a stable, protective oxide layer on the surface of the titanium.

This characteristic boundary, not as it were, avoids the corruption of the embed but also contributes to its long-term soundness and biocompatibility. The resistance to erosion guarantees that the titanium plate keeps up its basic astuteness over time, lessening the need for modification surgeries and upgrading quiet results.

Excellent Biocompatibility

Biocompatibility is a crucial factor in the success of any medical implant, and titanium plates excel in this aspect. The human body shows remarkable tolerance to titanium, with minimal allergic or inflammatory responses. This high level of biocompatibility is due to the inert nature of titanium and its ability to form a stable oxide layer that interacts favorably with surrounding tissues.

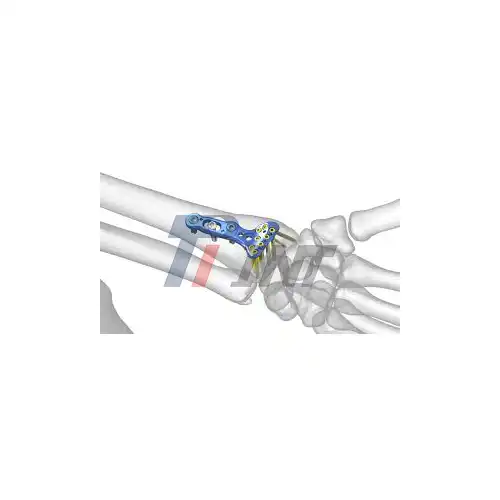

The biocompatibility of titanium plates extends beyond mere tolerance; it actively promotes osseointegration – the direct structural and functional connection between living bone tissue and the surface of the implant. This integration is vital for the long-term stability and function of orthopedic implants, allowing for secure fixation and load transfer between the implant and the bone.

|

|

Advanced Manufacturing Techniques for Enhanced Performance

Precision Machining and Forming

The production of medical titanium plates involves sophisticated manufacturing techniques that contribute significantly to their performance and reliability. Precision machining allows for the creation of plates with exacting dimensions and surface finishes, crucial for proper fit and function in the body.

Progressive shaping forms, such as cold working and toughening, can be utilized to tailor the mechanical properties of the titanium plates. These strategies can improve quality, ductility, or weakness resistance, depending on the particular prerequisites of the implant's intended utilization. The capacity to fine-tune these properties guarantees that each titanium plate is optimized for its specific application, whether it's a load-bearing plate for a broken femur or a fragile work for orbital floor recreation.

Surface Treatments and Coatings

The surface characteristics of medical titanium plates play a crucial role in their performance and integration with the body. Various surface treatments and coatings can be applied to enhance specific properties or functionalities. For instance, roughening the surface through processes like acid etching or sandblasting can increase the surface area for bone contact, promoting faster and stronger osseointegration.

Coatings such as hydroxyapatite, a mineral component of natural bone, can be applied to titanium plates to further enhance their bioactive properties. These coatings can stimulate bone growth and accelerate the healing process. Other surface modifications may focus on improving wear resistance, reducing bacterial adhesion, or enhancing the plate's visibility in medical imaging.

Quality Control and Certification

The manufacturing of medical titanium plates is subject to stringent quality control measures and regulatory standards. Reputable manufacturers, such as Baoji INT Medical Titanium Co., Ltd., adhere to international certifications like ISO9001:2015 for quality management systems and ISO13485:2016 specifically for medical devices. These certifications ensure that every step of the production process, from raw material selection to final inspection, meets the highest standards of quality and consistency.

Additionally, medical titanium plates often undergo rigorous testing to verify their mechanical properties, biocompatibility, and long-term performance. This may include fatigue testing, corrosion resistance evaluations, and in vitro and in vivo biocompatibility assessments. The CE marking for medical devices in the European Union further attests to the safety and performance of these implants.

Customization and Versatility in Medical Applications

Tailored Solutions for Diverse Surgical Needs

The versatility of medical titanium plates is evident in their wide range of applications across various surgical specialties. From orthopedics to maxillofacial surgery, these implants can be customized to meet the specific needs of each patient and procedure. The ability to tailor the size, shape, and properties of titanium plates allows surgeons to address complex anatomical challenges and optimize treatment outcomes.

For instance, in craniofacial reconstruction, titanium plates can be precisely contoured to match the patient's facial anatomy, ensuring both functional restoration and aesthetic results. In spinal surgery, specialized titanium plates can be designed to provide the necessary stability while accommodating the unique biomechanics of the spine.

Innovative Designs for Enhanced Functionality

The field of medical titanium plates is continually evolving, with innovative designs pushing the boundaries of what's possible in surgical implants. These advancements often focus on improving the plate's interaction with biological tissues, enhancing its mechanical performance, or facilitating minimally invasive surgical techniques.

Examples of innovative designs include:

- Low-profile plates that minimize soft tissue irritation

- Locking plate systems that provide enhanced stability in osteoporotic bone

- Biodegradable coatings that can deliver localized drug therapy

- Porous titanium structures that mimic the architecture of natural bone

Compatibility with Modern Imaging Techniques

An often overlooked but crucial aspect of medical titanium plates is their compatibility with modern imaging technologies. Unlike some metals that can cause significant artifacts in CT or MRI scans, titanium produces minimal interference. This characteristic is invaluable for post-operative monitoring and long-term follow-up, allowing healthcare providers to accurately assess healing progress and detect any potential complications.

The radiolucency of titanium also facilitates intraoperative imaging, enabling surgeons to verify the precise placement of implants during complex procedures. This capability enhances surgical accuracy and can contribute to improved outcomes and reduced operative times.

Conclusion

Medical titanium plates represent a pinnacle of biomedical engineering, offering an unparalleled combination of durability and biocompatibility. Their remarkable properties, advanced manufacturing techniques, and versatile applications have revolutionized the field of surgical implants, providing surgeons with powerful tools to address complex medical challenges.

As research continues and manufacturing technologies advance, we can expect even more innovative developments in medical titanium plates, further enhancing their performance and expanding their applications. For patients, these advancements translate to improved surgical outcomes, faster recovery times, and enhanced quality of life.

For those seeking high-quality medical titanium products, including plates, rods, and custom solutions, Baoji INT Medical Titanium Co., Ltd. stands as a trusted manufacturer with a commitment to excellence and innovation. To learn more about their comprehensive range of medical titanium solutions, please contact them at export@tiint.com.

2025-06-06 15:10:10

2025-06-06 15:10:10

_1752819172472.webp)

_1750662961697.webp)