The Remarkable Properties of Titanium Rods in Medical Applications

Titanium rods have become an indispensable tool in modern orthopedic surgery, particularly in spinal fusion and fracture recovery procedures. Their exceptional properties make them uniquely suited for medical applications, offering numerous advantages over traditional materials.

Biocompatibility: A Perfect Match for Human Tissue

One of the most crucial aspects of any medical implant is its biocompatibility. Titanium rod medical devices excel in this area, as they are remarkably well-tolerated by the human body. The material's ability to integrate with surrounding tissues without triggering adverse reactions is a key factor in its widespread use. This biocompatibility significantly reduces the risk of implant rejection, allowing for more successful and longer-lasting surgical outcomes.

The human body's acknowledgment of titanium is due to its capacity to frame a steady oxide layer on its surface. This layer acts as a defensive obstruction, anticipating erosion and minimizing the discharge of metal particles into the encompassing tissues. As a result, patients encounter less complications and a lower hazard of unfavorably susceptible responses compared to other metallic inserts.

Strength and Durability: Supporting Recovery with Confidence

When it comes to spinal fusion and fracture recovery, the strength and durability of the implant are paramount. Titanium rod medical devices offer an exceptional strength-to-weight ratio, providing robust support without adding unnecessary bulk. This characteristic is particularly beneficial in load-bearing applications, such as spinal fusion surgeries.

The tensile strength of Grade 5 titanium alloy (Ti6Al4V ELI) used in medical rods can reach up to 860 MPa, with a yield strength of 795 MPa. This impressive strength ensures that the rods can withstand the significant forces exerted on the spine during daily activities and rehabilitation exercises. Moreover, the material's 10% elongation property allows for some flexibility, which is crucial in mimicking the natural movement of the spine and reducing stress on adjacent vertebrae.

Corrosion Resistance: Ensuring Long-Term Reliability

The human body presents a challenging environment for implants, with constant exposure to bodily fluids and potential electrochemical reactions. Titanium rod medical devices shine in this aspect, thanks to their exceptional corrosion resistance. This property is vital for maintaining the integrity of the implant over extended periods, often lasting the patient's lifetime.

The corrosion resistance of titanium is attributed to its ability to form a passive oxide layer spontaneously when exposed to oxygen. This layer acts as a protective barrier, preventing further oxidation and degradation of the material. As a result, titanium rods can maintain their structural integrity and performance even in the harsh biological environment of the human body, ensuring long-term reliability and patient safety.

Enhancing Spinal Fusion Procedures with Titanium Rods

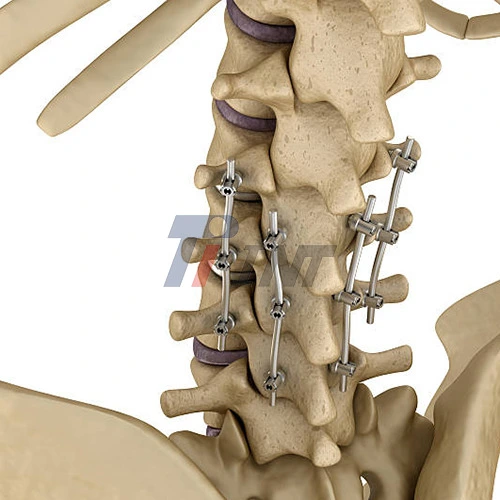

Spinal fusion is a complex surgical procedure aimed at joining two or more vertebrae to eliminate motion between them. Titanium rod medical devices have significantly improved the outcomes of these surgeries, offering several advantages over traditional methods.

Promoting Faster and More Reliable Fusion

The use of titanium rods in spinal fusion procedures has been shown to promote faster and more reliable bone fusion. The biocompatible nature of titanium allows for better osseointegration, where the surrounding bone tissue grows directly onto the surface of the implant. This intimate contact between the rod and the bone accelerates the fusion process and results in a stronger, more stable connection.

Furthermore, the surface finish of titanium rods can be customized to enhance bone growth. Options such as sandblasted or machined surfaces increase the surface area for bone contact, promoting even better osseointegration. This customization capability allows surgeons to choose the most appropriate surface finish based on the specific needs of each patient and the particular fusion site.

Minimizing Adjacent Segment Disease

One of the concerns in spinal fusion surgeries is the potential development of adjacent segment disease, where the vertebrae above and below the fused segment experience increased stress and degeneration. Titanium rod medical devices help mitigate this risk due to their unique combination of strength and flexibility.

The high strength of titanium allows for the use of smaller diameter rods, typically ranging from 3mm to 6mm for spinal applications. These smaller rods provide adequate support while minimizing the rigidity of the construct. The slight flexibility of titanium rods helps to distribute forces more evenly along the spine, reducing the stress concentration on adjacent segments and potentially lowering the risk of adjacent segment disease.

Improving Post-Operative Imaging

Another significant advantage of titanium rod medical devices in spinal fusion procedures is their compatibility with post-operative imaging techniques. Unlike stainless steel implants, titanium produces minimal artifacts in CT and MRI scans, allowing for clearer and more accurate imaging of the fusion site and surrounding tissues.

This improved imaging capability is crucial for assessing the progress of fusion, detecting any potential complications, and planning further treatments if necessary. The ability to obtain clear images without significant metal artifacts enhances the surgeon's ability to monitor the patient's recovery and make informed decisions about ongoing care.

Accelerating Fracture Recovery with Titanium Rod Implants

Beyond spinal fusion, titanium rod medical devices play a vital role in the treatment of complex fractures, particularly in long bones such as the femur, tibia, and humerus. The unique properties of titanium contribute to improved fracture healing and patient outcomes.

Providing Stable Fixation for Optimal Healing

The primary goal in fracture treatment is to provide stable fixation that allows for proper alignment and healing of the bone. Titanium rods excel in this aspect due to their high strength and excellent fatigue resistance. The fatigue resistance of titanium is particularly crucial in load-bearing bones, where the implant must withstand repeated stress cycles during the healing process.

The customizable length of titanium rods, which can be manufactured up to 6 meters long, allows surgeons to select the perfect size for each patient's specific fracture pattern and bone length. This customization ensures optimal fixation and alignment, promoting faster and more reliable fracture healing.

Reducing the Risk of Infection

Infection is a serious concern in any surgical procedure, particularly in fracture treatment where the implant is in close contact with damaged tissues. Titanium rod medical devices offer a significant advantage in this regard due to their inherent resistance to bacterial colonization.

The surface properties of titanium, including its oxide layer, make it less hospitable for bacteria to adhere and form biofilms compared to other metals. This characteristic, combined with proper surgical techniques and post-operative care, can contribute to a lower risk of implant-associated infections, leading to better patient outcomes and reduced healthcare costs.

Facilitating Early Mobilization and Rehabilitation

One of the key factors in successful fracture recovery is early mobilization and rehabilitation. Titanium rod medical devices, with their excellent strength-to-weight ratio, allow for weight-bearing and movement sooner after surgery compared to traditional treatment methods.

The lightweight nature of titanium rods, combined with their high strength, provides stable fixation without adding significant weight to the limb. This balance allows patients to begin controlled movement and weight-bearing exercises earlier in their recovery process, promoting faster healing, reducing muscle atrophy, and improving overall functional outcomes.

Long-Term Performance and Reduced Need for Removal

Unlike some other implant materials, titanium rod medical devices often do not require removal after the fracture has healed. The exceptional biocompatibility and corrosion resistance of titanium mean that these implants can remain in place indefinitely without causing adverse effects or compromising bone strength.

This long-term performance eliminates the need for a second surgery to remove the implant, reducing the overall risk to the patient and lowering healthcare costs. In cases where removal is necessary or desired, the properties of titanium also facilitate easier extraction compared to other materials that may have become more firmly integrated with the bone.

Conclusion

Titanium rod medical devices have undeniably transformed the landscape of spinal fusion and fracture recovery procedures. Their unique combination of biocompatibility, strength, durability, and corrosion resistance makes them an ideal choice for these challenging orthopedic applications. As medical technology continues to advance, we can expect further innovations in titanium implant design and manufacturing, leading to even better patient outcomes and quality of life.

For those interested in learning more about high-quality medical titanium products, including rods, plates, and custom solutions, please don't hesitate to contact us at export@tiint.com. Our team of experts is dedicated to providing cutting-edge titanium solutions that meet the highest standards of quality and performance in the medical field.

2025-10-10 08:47:05

2025-10-10 08:47:05

_1753426579714.webp)

_1752463324629.webp)

_1752462435099.webp)

_1755495780573.jpg)

_1749195818446.webp)

_1749191822714.webp)

_1755062186746.jpg)