The Advantages of Titanium Plates in Wrist Fracture Recovery

When it comes to treating wrist fractures, titanium plates have become the go-to solution for orthopedic surgeons. These remarkable implants offer a myriad of benefits that contribute to faster and more effective recovery. Let's delve into the key advantages of using titanium plates for broken wrists:

Unparalleled Biocompatibility

One of the most significant advantages of titanium plates is their exceptional biocompatibility. This means that the human body readily accepts titanium without triggering adverse reactions or rejections. The biocompatibility of titanium plates ensures a safer surgical experience and minimizes the risk of complications during the healing process. Patients can have peace of mind knowing that their body is unlikely to react negatively to the implant, allowing for a smoother recovery journey.

Lightweight Yet Incredibly Strong

Titanium plates boast an impressive strength-to-weight ratio, making them ideal for wrist fracture recovery. Despite being remarkably lightweight, these plates possess the strength necessary to provide stable fixation for broken bones. This unique combination of properties offers several benefits:

- Enhanced patient comfort due to the lightweight nature of the implant

- Reduced strain on surrounding tissues and muscles

- Improved mobility during the recovery period

- Adequate support for proper bone alignment and healing

The lightweight characteristic of titanium plate for broken wrist contributes to a more comfortable recovery experience without compromising on the structural support required for optimal healing.

Corrosion Resistance for Long-Term Reliability

Another notable advantage of titanium plates is their exceptional resistance to corrosion. This property is particularly important for medical implants that need to withstand the body's internal environment over extended periods. The corrosion-resistant nature of titanium plates offers several benefits:

- Extended lifespan of the implant

- Reduced risk of implant degradation or failure

- Minimized chances of adverse tissue reactions caused by metal ion release

- Improved long-term stability and performance

With their ability to resist corrosion, titanium plates provide a reliable and durable solution for wrist fracture recovery, ensuring long-lasting support throughout the healing process and beyond.

The Science Behind Titanium Plates: Technical Features and Performance

To truly appreciate the effectiveness of titanium plates in wrist recovery, it's essential to understand the scientific principles and technical features that make them such a valuable tool in orthopedic surgery. Let's explore the key technical aspects that contribute to the superior performance of titanium plates for broken wrists:

Mechanical Properties and Structural Integrity

Titanium plates are engineered to possess specific mechanical properties that make them ideal for orthopedic applications. These properties include:

- High tensile strength: Titanium plates can withstand significant stress without deforming or breaking, ensuring stable fixation of bone fragments.

- Low elastic modulus: This property allows titanium plates to flex slightly under load, reducing stress shielding and promoting healthy bone remodeling.

- Fatigue resistance: Titanium plates can withstand repeated loading cycles without experiencing material failure, crucial for long-term implant success.

The combination of these mechanical properties ensures that titanium plates provide robust and reliable support throughout the wrist recovery process, even under varying loads and stresses.

Surface Characteristics and Osseointegration

The surface characteristics of titanium plates play a vital role in their performance and integration with surrounding bone tissue. Key features include:

- Roughened surface texture: This promotes better adhesion of bone cells to the implant surface, enhancing osseointegration.

- Oxide layer formation: Titanium naturally forms a stable oxide layer on its surface, contributing to its biocompatibility and corrosion resistance.

- Potential for bioactive coatings: Some titanium plates may incorporate bioactive coatings to further enhance bone-implant integration and healing.

These surface characteristics contribute to the strong bond between the titanium plate for broken wrist and the surrounding bone, promoting faster healing and improved long-term stability of the wrist fracture repair.

Customization and Precision Engineering

Advancements in manufacturing technologies have enabled the production of highly customized titanium plates for broken wrists. This customization offers several advantages:

- Anatomical contouring: Plates can be pre-contoured to match the specific anatomy of the wrist, ensuring a better fit and reducing the need for intraoperative bending.

- Variable thickness designs: Plates can be engineered with varying thicknesses to optimize strength in high-stress areas while minimizing bulk in other regions.

- Locking screw technology: Many titanium plates incorporate locking screw mechanisms, enhancing stability and reducing the risk of screw loosening.

The ability to customize titanium plates allows surgeons to choose the most appropriate implant for each patient's unique fracture pattern and anatomy, leading to improved surgical outcomes and patient satisfaction.

Titanium Plates in Action: Surgical Application and Recovery Process

Understanding how titanium plates are applied during surgery and their role in the recovery process provides valuable insights into their effectiveness in treating wrist fractures. Let's examine the surgical application of titanium plates and the subsequent recovery journey:

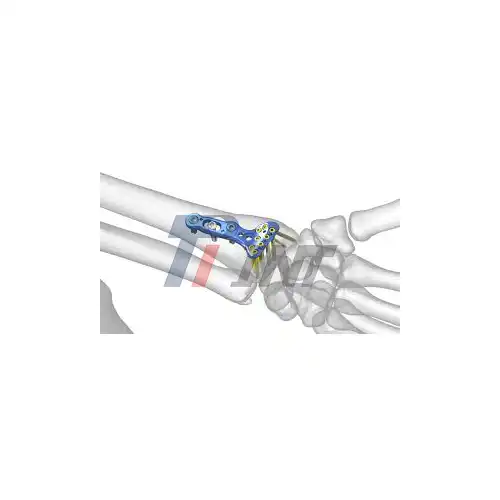

Surgical Procedure and Implantation

The surgical procedure for implanting a titanium plate for a broken wrist typically involves the following steps:

- Anesthesia administration and surgical site preparation

- Incision and exposure of the fractured wrist bones

- Reduction of the fracture to align the bone fragments

- Selection and positioning of the appropriate titanium plate

- Fixation of the plate using titanium screws

- Final adjustments and verification of proper alignment

- Closure of the incision and application of a sterile dressing

The precision and skill of the surgeon, combined with the quality of the titanium plate for broken wrist, are crucial factors in ensuring a successful implantation and optimal fracture fixation.

Post-Operative Care and Rehabilitation

Following the surgical implantation of a titanium plate, patients undergo a carefully planned post-operative care and rehabilitation program. This typically includes:

- Initial immobilization: The wrist is usually immobilized with a splint or cast for a period of time to protect the surgical site and allow initial healing.

- Pain management: Appropriate pain medications and techniques are employed to ensure patient comfort during the early stages of recovery.

- Gradual mobilization: As healing progresses, patients begin gentle range-of-motion exercises under the guidance of a physical therapist.

- Strengthening exercises: Progressive strengthening exercises are introduced to rebuild muscle strength and improve wrist function.

- Occupational therapy: Patients may receive occupational therapy to regain skills needed for daily activities and work-related tasks.

The stability provided by the titanium plate allows for earlier mobilization and more effective rehabilitation, potentially leading to faster recovery and improved functional outcomes.

Long-Term Outcomes and Implant Durability

The long-term success of wrist fracture treatment using titanium plates depends on various factors, including:

- Proper surgical technique and implant placement

- Patient compliance with post-operative instructions and rehabilitation protocols

- The nature and severity of the initial fracture

- Individual patient factors such as age, overall health, and bone quality

In most cases, titanium plates for broken wrists demonstrate excellent long-term durability and performance. The corrosion-resistant nature of titanium and its biocompatibility contribute to the longevity of the implant. Many patients can expect to retain the titanium plate indefinitely without complications, although in some cases, removal may be considered if the implant causes discomfort or interferes with joint function after complete healing.

Conclusion

Titanium plate for broken wrist have revolutionized the treatment of wrist fractures, offering a combination of strength, biocompatibility, and durability that significantly enhances the recovery process. From their superior mechanical properties to their ability to integrate seamlessly with bone tissue, these implants provide the stable fixation necessary for optimal healing. As medical technology continues to advance, we can expect further innovations in titanium plate design and application, potentially leading to even better outcomes for patients with broken wrists.

For those seeking high-quality titanium plates for orthopedic applications, Baoji INT Medical Titanium Co., Ltd. offers a comprehensive range of medical titanium products. With over 30 years of experience in the research, development, and production of titanium materials, INT has established itself as a leader in the medical titanium industry. To learn more about their products or to discuss your specific needs, please contact them at export@tiint.com.

2025-08-22 09:47:23

2025-08-22 09:47:23

_1750664314563.webp)