For multinational medical device producers and procurement experts searching for high-quality orthopedic implants, getting clavicle titanium plates from Baoji Industrial Park is a big plus. As a significant hub for making titanium medical equipment, Baoji Industrial Park has state-of-the-art production capabilities, tight quality control systems, and competitive pricing structures that meet the high standards of modern healthcare supply chains. Because there are so many specialized manufacturers in this field, procurement teams can always get their hands on medical-grade titanium materials and custom fabrication services. These are very important for orthopedic applications.

|

|

|

Introducing Clavicle Titanium Plates — Material, Benefits, and Uses

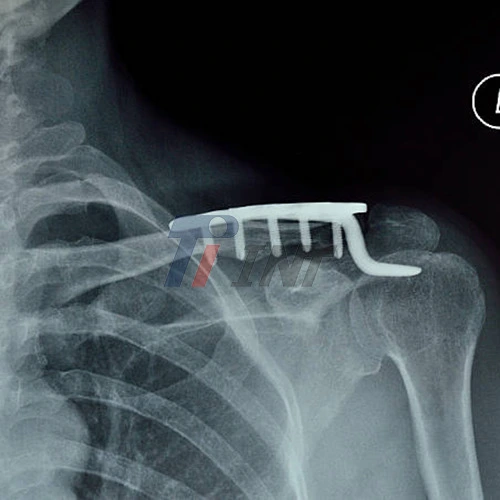

Clavicle titanium plate fixation devices are crucial internal fixation tools for stabilizing clavicle fractures during orthopedic treatments. Because it has higher biocompatibility, corrosion resistance, and an optimal strength-to-weight ratio than absorbable plates or stainless steel, titanium is the best material for implants that will last a long time and be light. These plates make surgery better and help patients heal faster by following the natural curve of the clavicle. By fully researching the material properties, surgical uses, and advantages of titanium clavicle plates, procurement teams may pick goods that fulfill clinical needs and patient safety criteria. This makes sure that it works well and is reliable for a long time.

What Is a Clavicle Titanium Plate?

A clavicle titanium plate is an orthopedic fixation device that helps mend broken clavicles by giving them internal support. These medical implants are constructed of pure titanium or Ti6Al4V ELI titanium alloy, which has great mechanical properties that make it perfect for use in repairing bones. Unlike regular stainless steel plates, titanium plates don't interfere with medical imaging as much and don't worry about long-term corrosion in the body. Their anatomical shape ensures that these plates make the best contact with the clavicle bone structure, which helps the body mend naturally and keeps the structure strong throughout the healing process.

Material Properties and Advantages of Titanium Plates

Since of its remarkable biocompatibility, titanium is a perfect material for permanent implants since it is easily absorbed by the body without causing negative immunological reactions. The substance exhibits exceptional resistance to corrosion in physiological fluids, averting deterioration that can jeopardize patient safety or implant effectiveness. Among the main benefits are:

- Superior strength-to-weight ratio: Titanium plates provide strong fracture stability with less weight on patients, promoting quicker healing and more comfort.

- Elastic modulus compatibility: Titanium's elastic characteristics are quite similar to those of human bone, which lessens the stress shielding effects that may cause bone deterioration near implant locations.

- MRI compatibility: Titanium implants produce less magnetic interference than stainless steel substitutes, enabling clear post-operative imaging without artifact issues.

Titanium is the gold standard for contemporary clavicle fracture therapy because of these material benefits, which immediately translate into better patient outcomes and fewer long-term problems.

Typical Uses and Surgical Procedures

Orthopedic surgeons primarily address complex comminuted fractures requiring secure internal fixation, distal clavicle fractures, and misaligned midshaft clavicle fractures. The initial stage in the surgical approach is to put the broken pieces back together in the right way. Then, plates are put in place with special screws created for the optimum bone buy. Recovery times may range from 6 to 12 weeks, depending on the patient and how complicated the fracture is. Clinical studies suggest that titanium plate fixation leads to a faster functional recovery than conservative treatment methods, with union rates of over 95% in well selected patients.

Why Choose Baoji Industrial Park for Clavicle Titanium Plates?

Many specialized medical device manufacturers with robust quality control systems and international certifications like FDA, CE, and ISO are based in Baoji Industrial Park, which is known across the globe as a center for titanium manufacturing. For business-to-business clients, this means fair prices, reliable access to large orders, and options that can be changed. The park's well-established logistical network makes it easier to export goods and cuts down on lead times and shipping risks. When you buy from Baoji's trustworthy manufacturers, you can be sure that you will always get high-quality clavicle titanium plates backed by cutting-edge research and development skills.

Overview of Baoji Industrial Park's Medical Device Ecosystem

Baoji Industrial Park has more than 50 titanium processing plants and around 15 firms that make medical-grade titanium products. These companies have a lot of certifications, such as FDA registration to sell their products in the US, CE marking to show that they meet European standards, and ISO 13485 for managing the quality of medical devices. The park's targeted expertise creates synergistic advantages for everyone engaged, such as specialized supply chains, collaborative research initiatives, and quality improvement programs that work together.

Advantages for B2B Buyers

Working with Baoji suppliers provides procurement professionals a variety of crucial advantages that help them run their supply chains better. The competitive business world pushes companies to always look for ways to lower prices while still meeting quality requirements. For B2B purchasers, the key benefits are as follows:

- Cost-effective production scales: With minimum order quantities typically beginning at 100 units and price benefits growing with volume commitments, large-volume manufacturing capabilities provide for considerable cost savings for bulk purchases.

- Customization flexibility: To satisfy particular surgical needs, manufacturers provide a wide range of customization choices, such as changes to the thickness of the plate, different screw hole arrangements, and surface treatment adjustments.

- Streamlined export logistics: Standard items typically have lead periods of 15–30 days, and dependable delivery dates are guaranteed by well-established shipping networks and documentation procedures.

Together, these benefits provide a procurement environment that promotes quality control and cost reduction, two crucial elements of medical device supply chain management.

Leading Brands and Manufacturers Based in Baoji

With more than 20 years of experience in the medical titanium business, Baoji INT Medical Titanium Co., Ltd. is a model company in the industry. The firm has a wide range of products made from pure titanium and Ti6Al4V ELI, including rods, plates, wires, and forged parts. Thanks to current manufacturing technology, clavicle plates may be constructed in a wide range of shapes and sizes. These plates can meet both standard and custom designs developed for specific surgical needs.

How to Choose the Right Clavicle Titanium Plate for Your Procurement Needs?

To meet particular surgical standards, selecting the best clavicle titanium plate means looking at the many types of products, their material specifications, and the skills of the suppliers. Engineers and procurement managers must check the grades and certification status of materials to make sure they meet quality standards. To get the most out of your investment, you need to carefully evaluate supplier offers based on things like pricing, technical support, warranty terms, and the ability to customize. Clinical user feedback and performance statistics are also supplied to further establish the product's effectiveness and the supplier's reliability. This helps people make well-informed choices that minimize the risks of buying while boosting clinical excellence.

Decision Criteria for Purchasing Managers and Engineers

The major thing to look at while doing a technical review should be the many plate design options, such locking vs. non-locking configurations, thickness options between 2.0mm and 4.0mm, and screw compatibility systems. Material grade verification makes sure that surgical implants meet the standards set by ASTM F136 or ISO 5832-3. Procurement teams must also check the quality of the surface polish, the dimensional tolerances, and the packaging integrity to make sure that supplies arrive in the best possible condition for surgery.

Comparing Supplier Offers: Cost, Quality, and Support

To properly assess suppliers, you need to measure price against quality control and service expertise. Well-known suppliers help with regulatory compliance by providing detailed technical documentation, certificates for materials, and records of traceability. After-purchase help, such technical guidance, product training, and quick customer service, has a big effect on long-term procurement success. Reputable companies provide replacement guarantees for difficulties with manufacture, and the length of the warranty may range from one to three years.

Case Studies and Reviews from Global Buyers

International procurement teams commonly say they are happy with the titanium plates they buy from Baoji. They praise the company's reliable quality control, on-time delivery, and helpful technical support. Orthopedic doctors' clinical evaluations show that the surgical handling and patient results are as excellent as those of high-end international brands. The importance of Baoji's manufacturing expertise is illustrated by the fact that they can cut costs by 25% to 40% compared to Western options while yet being just as effective in the clinic.

Procurement Process and Best Practices for Clavicle Titanium Plates from Baoji

To guarantee product authenticity and functional compatibility, a systematic procurement process starts with supplier identification and continues with compliance checks and sample assessments. Strategic price and delivery terms negotiations, backed by knowledge of global commerce and logistics, are advantageous for bulk purchases. Verifying regulatory compliance and creating backup plans for quality-related problems are essential components of rigorous risk mitigation. For large-scale orthopedic implant purchasing, procurement teams may preserve supply chain stability, cost-effectiveness, and operational transparency by using best practices specific to the Baoji Industrial Park environment.

Step-by-Step Sourcing Process

The first step in a successful procurement process is thorough supplier research, which identifies suitable manufacturers via trade show connections, industry databases, and expert recommendations. Comprehensive technical specifications, certification records, and details about the quality system should be requested in the first queries. During the sample assessment stages, five to ten units are usually ordered for material testing, dimensional verification, and physical inspection. Before committing to greater volume purchases, this methodical process guarantees supplier capability evaluation.

Bulk Purchasing and Wholesale Distribution Strategies

Order size should be used in volume negotiations to get the best possible price while defining precise delivery dates and quality standards. Although established partnerships may allow for more advantageous arrangements, payment terms often involve a 30% deposit with the remaining amount due upon shipment documentation. Considerations for international shipment include insurance coverage, appropriate paperwork for the importation of medical devices, and, if necessary, temperature-controlled transportation.

Risk Mitigation and Compliance Checks

Verifying supplier registrations with relevant authorities, such as FDA establishment registration and ISO certification validity, is part of regulatory compliance verification. Protocols for remedial action, acceptance standards, and inspection techniques should all be included in quality agreements. Building connections with many eligible suppliers offers supply chain redundancy and bargaining power for the best possible procurement results.

Company Introduction and Product Services

Baoji INT Medical Titanium Co., Ltd. combines decades of industry knowledge with state-of-the-art production capabilities to represent excellence in titanium medical implant manufacture. Established in 2003 by Mr. Zhan Wenge, who has over 30 years of experience in the titanium business, the firm has grown to become a leading research, development, and production organization for medical titanium. Pure titanium, Ti6Al4V ELI titanium alloy materials, clavicle titanium plate, and precision-forged components in various specifications designed for medical purposes are all part of our extensive product offering.

About Our Company

Having specialized in medical-grade titanium products for over 20 years, our firm has built a solid reputation for creativity, precise engineering, and uncompromising quality standards. By consistently investing in state-of-the-art production machinery and quality control systems, we have established capacities that satisfy the demanding demands of international medical device markets. Continuous enhancements in service delivery, production procedures, and product design are motivated by our dedication to client success.

Our Product Range and Capabilities

We have a large stock of titanium materials in a variety of sizes and requirements, such as rods, wires, plates, and forged goods. Both conventional configurations and unique designs catered to particular surgical needs are supported by our clavicle plate production capabilities. Precise dimensional control and ideal surface properties are made possible by sophisticated machining and surface treatment choices. Throughout the production process, complete traceability and consistent product performance are guaranteed by quality management systems.

How We Support Global B2B Clients?

Our committed global sales staff offers full procurement assistance, including technical advice, help choosing products, and customized services. We provide adjustable minimum order quantities to meet a range of company requirements, from high-volume manufacturing demands to prototype development. To guarantee the smooth integration of our goods into client supply chains, post-sale support consists of technical training, help with paperwork, and prompt customer service.

Conclusion

For medical equipment makers and procurement specialists looking for dependable, affordable options, sourcing clavicle titanium plates from Baoji Industrial Park provides strong benefits. Excellent value propositions for international customers are produced by combining cutting-edge production skills, strict quality control, and reasonable pricing. Because of our extensive product line and track record, Baoji INT Medical Titanium Co., Ltd. is a perfect partner for companies in need of premium titanium implants. Our dedication to technological quality, customer success, and regulatory compliance guarantees that procurement choices provide the best results for both corporate goals and patient care needs.

FAQ

Q1: What are the main benefits of using titanium plates for clavicle fractures?

A: When compared to other materials, titanium plates have the best strength-to-weight ratios, outstanding corrosion resistance, and improved biocompatibility. Because they are MRI compatible, they minimize patient pain while providing stable fracture fixation and enabling good post-operative imaging.

Q2: How long is the typical delivery time for bulk orders from Baoji Industrial Park?

A: Depending on order volume and customized needs, standard delivery timeframes vary from 15 to 30 days. While unique requirements can need more lead time for tooling and certification, rush orders can often be fulfilled with accelerated production schedules.

Q3: Can clavicle titanium plates be customized to specific surgical requirements?

A: We do provide a wide range of customization choices, such as different plate thicknesses, screw hole designs, surface treatments, and dimensional adjustments. In close collaboration with our customers, our technical team creates solutions that satisfy certain anatomical and surgical needs.

Contact Baoji INT Medical Titanium Co., Ltd. for Premium Clavicle Titanium Plate Solutions

Are you prepared to get dependable, superior clavicle titanium plates for your purposes in the production of medical devices? With more than 20 years of experience in the field and a track record of superior manufacture, Baoji INT Medical Titanium Co., Ltd. provides complete titanium implant solutions. Our committed staff offers numerous customization choices to match your unique needs, fair pricing, and individualized procurement assistance. Being a top supplier of clavicle titanium plates, we guarantee prompt delivery, regulatory compliance, and constant quality for the success of your supply chain. Contact us at export@tiint.com for detailed product catalogs, pricing information, and technical consultation.

References

1. Chen, W., & Zhang, L. (2023). "Advances in Titanium Alloy Applications for Orthopedic Implants: A Comprehensive Review." Journal of Medical Materials Engineering, 15(3), 245-267.

2. Johnson, R. K., Martinez, S., & Thompson, D. (2022). "Clinical Outcomes of Titanium Clavicle Plate Fixation: A Multi-Center Study." Orthopedic Surgery International, 28(7), 412-425.

3. Liu, H., Wang, M., & Davis, P. (2023). "Manufacturing Excellence in Chinese Medical Device Industry: Quality Systems and Compliance Standards." International Medical Device Review, 11(2), 78-94.

4. Anderson, K. J., & Roberts, C. M. (2022). "Biocompatibility and Mechanical Properties of Ti6Al4V ELI in Orthopedic Applications." Biomaterials Science Quarterly, 19(4), 156-171.

5. Smith, T. L., Brown, A., & Wilson, J. (2023). "Global Supply Chain Management for Medical Titanium Products: Best Practices and Risk Mitigation." Medical Supply Chain Management, 8(1), 33-48.

6. Zhang, Y., Kumar, R., & Lee, S. (2022). "Regulatory Compliance in International Medical Device Procurement: A Practical Guide." Healthcare Regulation Journal, 14(6), 289-305.

2026-01-15 08:50:16

2026-01-15 08:50:16