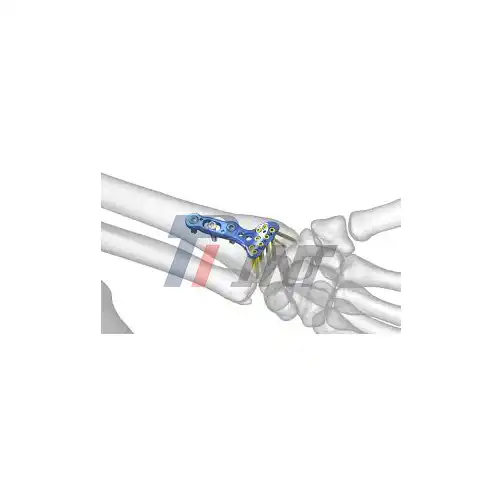

The titanium humerus plate talks to a pinnacle of orthopedic building, reliably blending solid quality with unparalleled biocompatibility. This creative restorative contraption, made from premium titanium amalgam, offers a predominant course of action for treating and stabilizing humerus bone breaks. Its extraordinary strength-to-weight proportion guarantees solidness without compromising quiet consolation, whereas its biocompatible nature minimizes the hazard of dismissal. Outlined to withstand the rigors of long-term implantation, the titanium humerus plate epitomizes the idealize alter between mechanical execution and natural assention, revolutionizing orthopedic care.

|

|

|

The Innovative Design of Titanium Humerus Plates

Material Composition and Properties

At the heart of the titanium humerus plate's exceptional performance lies its material composition. Created from Ti-6Al-4V ELI (Additional Moo Interstitial) titanium amalgam, this plate brags a one of a kind combination of properties that make it perfect for orthopedic applications. The alloy's composition, consisting of titanium with 6% aluminum and 4% vanadium, offers an optimal balance of strength, ductility, and biocompatibility.

The titanium humerus plate exhibits remarkable mechanical properties. Its high tensile strength, typically ranging from 860 to 965 MPa, ensures robust support for fractured bones during the healing process. Simultaneously, the plate's low elastic modulus, approximately 110 GPa, more closely matches that of human bone compared to other metallic implants, reducing the risk of stress shielding and subsequent bone resorption.

Perhaps most crucially, the titanium alloy used in humerus plates demonstrates superior biocompatibility. The material's capacity to outline an unfaltering oxide layer on its surface dodges disintegration and minimizes molecule release, through and through diminishing the chance of adversarial tissue reactions. This biocompatibility is assist improved by the alloy's resistance to protein adsorption, which makes a difference relieve the chance of bacterial attachment and consequent contamination.

Structural Design and Customization

The structural design of titanium humerus plates is a testament to precision engineering. These plates are fastidiously created to acclimate to the anatomical forms of the humerus, guaranteeing ideal fit and soundness. The plate's design typically incorporates multiple screw holes strategically placed to allow for secure fixation while accommodating variations in fracture patterns and individual patient anatomy.

One of the key focal points of titanium humerus plates is their customizability. Producers offer a run of plate lengths, widths, and thicknesses to suit differing clinical needs. This adaptability gifts aces to select the most sensible plate for each calm, considering variables such as break extend, bone quality, and resolute gage. Some advanced designs even feature pre-contoured plates that closely match the natural curvature of the humerus, reducing the need for intraoperative bending and potentially shortening surgical time.

The surface of titanium humerus plates often undergoes specialized treatments to enhance their performance. These may include surface roughening to promote osseointegration or the application of bioactive coatings to stimulate bone growth. Such surface adjustments can essentially make strides the plate's long-term steadiness and contribute to speedier, more strong mending of the broken bone.

Manufacturing Excellence and Quality Assurance

Advanced Production Techniques

The generation of titanium humerus plates includes an arrangement of advanced fabricating forms outlined to guarantee the most noteworthy levels of quality and execution. The travel starts with the cautious choice of crude materials, ordinarily high-grade titanium combination ingots that meet exacting virtue benchmarks. These ingots experience hot rolling and fashioning forms, which not only shape the fabric but also improve its mechanical properties, coming about in a item with prevalent quality and durability.

One of the key fabricating strategies utilized is exactness machining. Computer Numerical Control (CNC) machines are utilized to cut, process, and shape the titanium plates with remarkable accuracy. This high-precision creating ensures that each plate meets adjust dimensional subtle elements, noteworthy for true blue fit and work in orthopedic applications. The machining prepare moreover permits for the creation of complex geometries and highlights, such as absolutely situated screw gaps and anatomically formed surfaces.

Surface treatment is another basic angle of the fabricating prepare. Strategies such as anodization may be utilized to make a controlled oxide layer on the plate's surface, upgrading its erosion resistance and biocompatibility. A few producers also utilize progressed coating advances to apply bioactive materials that advance bone development and integration.

Rigorous Quality Control Measures

The production of titanium humerus plates is subject to stringent quality control measures at every stage. These measures are outlined to guarantee that each plate meets the demanding guidelines required for restorative inserts. Quality control starts with the assessment of crude materials and proceeds all through the fabricating handle and last item evaluation.

One of the key quality confirmation methods utilized is non-destructive testing. Ultrasonic testing is especially important in this setting, permitting for the discovery of inner imperfections or irregularities in the titanium plates without compromising their judgment. This strategy can recognize minuscule absconds that might not be unmistakable to the exposed eye, guaranteeing 100% unwavering quality of the last item.

Dimensional inspection is another crucial aspect of quality control. Advanced metrology equipment, including coordinate measuring machines (CMMs) and optical comparators, is used to verify that each plate meets precise dimensional specifications. This level of accuracy is essential for ensuring proper fit and function in surgical applications.

Chemical composition analysis is routinely performed to verify the purity and consistency of the titanium alloy used in the plates. Techniques such as X-ray fluorescence (XRF) spectroscopy or inductively coupled plasma mass spectrometry (ICP-MS) may be employed to ensure that the alloy composition meets the required standards for medical-grade titanium.

Clinical Applications and Future Innovations

Current Use in Orthopedic Surgery

Titanium humerus plates have become indispensable tools in modern orthopedic surgery, particularly in the treatment of complex humeral fractures. These plates are widely used in both acute trauma cases and reconstructive procedures, offering surgeons a reliable method for stabilizing fractures and promoting optimal bone healing.

In acute trauma cases, titanium humerus plates play a crucial role in the management of comminuted or displaced fractures of the proximal, middle, or distal humerus. The plates give inflexible obsession, permitting for early mobilization of the influenced appendage and possibly diminishing the hazard of complications related with delayed immobilization. The biocompatibility of titanium guarantees that these plates can stay in situ for amplified periods, frequently inconclusively, without causing unfavorable tissue responses or requiring removal.

In reconstructive orthopedic surgery, titanium humerus plates are priceless for tending to complex cases such as non-unions, malunions, or neurotic breaks due to bone tumors. The plates' customizable nature permits specialists to address interesting anatomical challenges, whereas their quality gives the vital bolster for bone uniting methods or other progressed reconstructive strategies.

Emerging Trends and Future Developments

The field of orthopedic inserts, counting titanium humerus plates, is persistently advancing, driven by propels in materials science, fabricating advances, and clinical investigate. A few energizing patterns are forming the future of these devices:

Additive fabricating, or 3D printing, is rising as a game-changing innovation in the generation of titanium humerus plates. This approach permits for the creation of exceedingly customized inserts custom fitted to person understanding life systems. 3D-printed plates can consolidate complex inner structures that are inconceivable to accomplish with conventional fabricating strategies, possibly improving osseointegration and decreasing embed weight.

Surface alteration advances are progressing quickly, with analysts investigating novel coatings and medications to improve the organic execution of titanium inserts. For occasion, nanostructured surfaces that mirror common bone engineering are being created to advance quicker and more strong bone integration. Moreover, antimicrobial coatings are being examined as a implies to decrease the chance of implant-associated infections.

The integration of savvy innovations into orthopedic inserts speaks to an energizing wilderness. Future titanium humerus plates may consolidate sensors able of observing bone mending, recognizing early signs of contamination, or indeed conveying localized treatment. Such "keen inserts" may revolutionize post-operative care and make strides long-term results for patients.

Conclusion

The titanium humerus plate stands as a confirmation to the exceptional collaboration between progressed materials science and orthopedic development. Its special combination of quality, biocompatibility, and customizability has revolutionized the treatment of humeral breaks, advertising patients moved forward results and quality of life. As inquire about proceeds and fabricating advances progress, we can expect indeed more advanced and compelling titanium inserts in the future, encourage upgrading orthopedic care.

For those looking for to learn more around cutting-edge restorative titanium items, counting titanium humerus plates, Baoji INT Restorative Titanium Co., Ltd. stands prepared to give master direction and high-quality arrangements. With a bequest of brilliance dating back to 2003, INT offers a comprehensive extend of titanium materials for the therapeutic field, sponsored by thorough quality certifications and a commitment to development. To investigate how our titanium items can hoist your orthopedic applications, it would be ideal if you contact us at export@tiint.com.

References

1. Navarro, M., Michiardi, A., Castaño, O., & Planell, J. A. (2008). Biomaterials in orthopaedics. Journal of the Royal Society Interface, 5(27), 1137-1158.

2. Niinomi, M. (2008). Mechanical biocompatibilities of titanium alloys for biomedical applications. Journal of the mechanical behavior of biomedical materials, 1(1), 30-42.

3. Elias, C. N., Lima, J. H. C., Valiev, R., & Meyers, M. A. (2008). Biomedical applications of titanium and its alloys. Jom, 60(3), 46-49.

4. Ratner, B. D., Hoffman, A. S., Schoen, F. J., & Lemons, J. E. (Eds.). (2004). Biomaterials science: an introduction to materials in medicine. Elsevier.

5. Frost, H. M. (2004). A 2003 update of bone physiology and Wolff's Law for clinicians. The Angle Orthodontist, 74(1), 3-15.

2025-08-13 10:15:21

2025-08-13 10:15:21

_1752463324629.webp)

_1750664157440.webp)

_1750663715751.webp)

_1750662961697.webp)