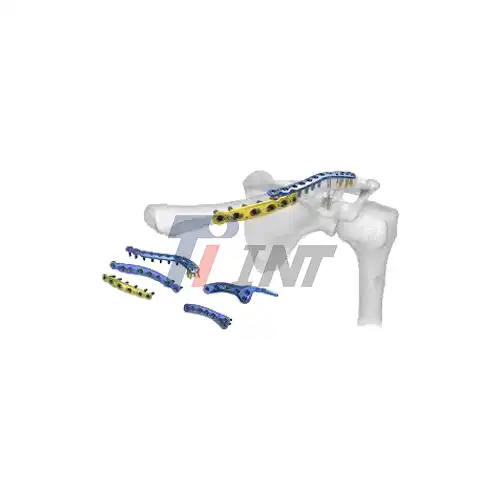

The Unique Properties of Titanium in Medical Applications

Biocompatibility: A Crucial Factor in Implant Success

Biocompatibility stands as a paramount consideration in the realm of medical implants, and titanium plate for collar bone excels in this aspect. The human body's remarkable acceptance of titanium stems from its ability to form a stable oxide layer upon exposure to oxygen. This phenomenon, known as passivation, creates a protective barrier that prevents corrosion and minimizes the risk of adverse reactions.

The biocompatibility of titanium extends beyond mere tolerance; it actively promotes osseointegration – the direct structural and functional connection between living bone tissue and the implant surface. This unique property facilitates faster healing and ensures a more secure fixation of the collar bone plate. As a result, patients experience reduced inflammation, decreased risk of rejection, and improved overall outcomes.

Strength-to-Weight Ratio: Balancing Support and Comfort

The exceptional strength-to-weight ratio of titanium plate for collar bone sets it apart from alternative materials. Despite its remarkably low density, titanium boasts a tensile strength comparable to steel. This unique combination allows for the creation of implants that provide robust support without imposing undue burden on the patient.

In the context of collarbone fractures, this property proves invaluable. The lightweight nature of titanium plates minimizes strain on surrounding tissues and reduces the risk of discomfort or irritation. Simultaneously, the material's inherent strength ensures that the plate can withstand the forces exerted during daily activities and support the bone throughout the healing process.

Corrosion Resistance: Ensuring Long-Term Reliability

The corrosive environment within the human body poses a significant challenge for implant materials. Titanium's exceptional resistance to corrosion makes it an ideal choice for long-term medical applications, including collar bone plates. The aforementioned oxide layer acts as a protective shield, preventing degradation of the implant over time.

This resilience translates to enhanced durability and reliability. Patients can trust that their titanium plate for collar bone will maintain its structural integrity and performance throughout the healing process and beyond. The reduced risk of implant failure or need for revision surgery contributes to improved patient outcomes and reduced healthcare costs.

Comparative Analysis: Titanium vs. Traditional Materials

Titanium vs. Stainless Steel: A New Standard in Orthopedic Implants

While stainless steel has long been used in orthopedic implants, titanium plate for collar bone represents a significant advancement in the field. Compared to stainless steel, titanium offers several distinct advantages:

- Reduced weight: Titanium is approximately 45% lighter than stainless steel, resulting in less strain on surrounding tissues and improved patient comfort.

- Superior biocompatibility: Titanium's excellent tissue response minimizes the risk of allergic reactions or implant rejection, which can be concerns with certain grades of stainless steel.

- Enhanced imaging compatibility: Titanium produces fewer artifacts in medical imaging studies, allowing for clearer post-operative evaluation and monitoring.

- Improved fatigue resistance: Titanium's fatigue strength surpasses that of stainless steel, ensuring better long-term performance under cyclic loading conditions.

Titanium vs. Polymer-Based Materials: Strength Meets Flexibility

Polymer-based materials, such as polyetheretherketone (PEEK), have gained popularity in certain orthopedic applications. However, titanium plate for collar bone offers unique benefits that make it the preferred choice for collarbone fractures:

- Higher strength: Titanium's superior mechanical properties provide more robust support for bone healing, particularly in load-bearing applications.

- Better osseointegration: While some polymers are biocompatible, they lack titanium's ability to promote direct bone ingrowth and attachment.

- Proven track record: Titanium has a long history of successful use in orthopedic implants, instilling confidence in both surgeons and patients.

- Versatility: Titanium can be easily customized and manufactured into various shapes and sizes to meet specific surgical needs.

Economic Considerations: Long-Term Value of Titanium Implants

While the initial cost of titanium plate for collar bone may be higher than some alternatives, its long-term value proposition is compelling. The durability and reliability of titanium implants often result in reduced need for revision surgeries or implant replacements. This translates to lower overall healthcare costs and improved patient satisfaction.

Furthermore, the faster healing and reduced complication rates associated with titanium implants can lead to shorter hospital stays and quicker returns to normal activities. These factors contribute to improved quality of life for patients and potential cost savings for healthcare systems.

Advancements in Titanium Plate Technology for Collar Bone Repair

Customization and 3D Printing: Tailoring Solutions to Individual Patients

The advent of 3D printing technology has revolutionized the production of titanium plate for collar bone. This innovative approach allows for the creation of patient-specific implants that precisely match the anatomy of each individual. The benefits of customized titanium plates include:

- Improved fit and stability: Custom-designed plates conform more closely to the patient's unique bone structure, enhancing fixation and reducing the risk of implant failure.

- Optimized stress distribution: Tailored designs can better distribute forces across the implant, potentially accelerating healing and reducing the risk of complications.

- Reduced surgical time: Pre-shaped plates that match the patient's anatomy can simplify the surgical procedure, potentially reducing operative time and associated risks.

Surface Modifications: Enhancing Osseointegration and Healing

Ongoing research in surface engineering has led to significant improvements in the performance of titanium plate for collar bone. Various surface modification techniques have been developed to enhance the implant's interaction with surrounding tissues:

- Plasma spraying: This technique creates a rough, porous surface that promotes bone ingrowth and stronger implant fixation.

- Nanostructured coatings: Advanced coatings can be applied to titanium surfaces to enhance bioactivity and stimulate faster bone formation.

- Antimicrobial treatments: Certain surface modifications can imbue titanium implants with antimicrobial properties, reducing the risk of post-operative infections.

Future Directions: Smart Implants and Bioactive Materials

The future of titanium plate for collar bone holds exciting possibilities. Emerging technologies are paving the way for "smart" implants that can actively participate in the healing process:

- Sensor-equipped plates: Integration of miniature sensors could allow for real-time monitoring of bone healing and early detection of potential complications.

- Drug-eluting implants: Titanium plates could be designed to slowly release growth factors or antibiotics, promoting faster healing and reducing infection risks.

- Bioactive coatings: Advanced coatings may further enhance the implant's ability to stimulate bone growth and accelerate the healing process.

As research in these areas progresses, we can expect to see even more sophisticated and effective titanium plate for collar bone solutions in the future.

Conclusion

In the realm of collar bone fracture treatment, titanium plate for collar bone stands out as the superior choice. Its unparalleled combination of biocompatibility, strength, and durability make it the ideal material for promoting optimal healing and patient outcomes. As technology continues to advance, we can expect even more innovative titanium-based solutions to emerge, further improving the standard of care for collarbone injuries.

For those seeking high-quality titanium plate for collar bone and other medical titanium products, Baoji INT Medical Titanium Co., Ltd. offers a comprehensive range of solutions backed by over 30 years of industry experience. To learn more about their advanced titanium implants and customized offerings, interested parties are encouraged to reach out via email at export@tiint.com.

2025-08-19 09:50:53

2025-08-19 09:50:53

_1750923514395.webp)

_1750663715751.webp)