The Science Behind Titanium Plates in Orthopedic Surgery

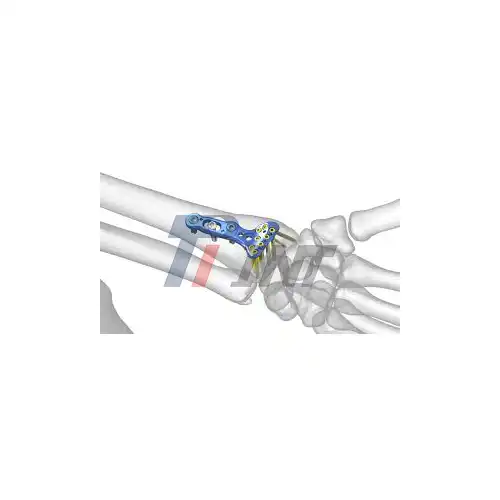

Titanium plates have revolutionized the field of orthopedic surgery, offering an interesting combination of properties that make them perfect for bone break recuperation. The use of titanium in restorative inserts dates back to the mid-20th century, and since that point, it has become the fabric of choice for numerous surgical applications.

One of the key reasons for titanium's notoriety in bone plates is its uncommon strength-to-weight proportion. In spite of being surprisingly lightweight, titanium boasts a noteworthy malleable quality, permitting it to withstand noteworthy pushes without misshaping or breaking. This characteristic is pivotal in bone break recuperation, as the plate must give satisfactory feedback to the recuperating bone while standing up to the strengths applied amid everyday exercises.

Another vital attribute of titanium is its biocompatibility. Unlike some other metals, titanium doesn't elicit an adverse immune response when implanted in the body. This property is due to the formation of a thin, stable oxide layer on the surface of the titanium, which acts as a barrier between the metal and the surrounding tissues. This oxide layer also contributes to titanium's resistance to corrosion, ensuring the longevity of the implant.

Furthermore, titanium exhibits a unique property called osseointegration. This phenomenon involves the direct structural and functional connection between living bone tissue and the surface of the implant. Osseointegration allows the titanium plate to become fully integrated with the surrounding bone, creating a strong and stable fixation that promotes optimal healing.

The manufacturing process of titanium plate for bone involves advanced techniques to ensure precision and quality. Companies like Baoji INT Medical Titanium Co., Ltd. utilize state-of-the-art equipment and adhere to stringent quality control measures to produce titanium plates that meet international standards. These plates undergo rigorous testing to ensure they can withstand the stresses of implantation and provide reliable support throughout the healing process.

Applications and Benefits of Titanium Plates in Fracture Treatment

Titanium plate for bone find applications in a wide range of orthopedic procedures, from simple fracture fixation to complex reconstructive surgeries. Their versatility makes them suitable for treating fractures in various parts of the body, including the skull, facial bones, spine, long bones of the arms and legs, and even small bones in the hands and feet.

In cranial and maxillofacial surgery, titanium plates play a crucial role in reconstructing facial features and protecting the brain. These plates can be custom-shaped to match the contours of the patient's face, ensuring both functional recovery and aesthetic outcomes. The low magnetic susceptibility of titanium also makes it compatible with magnetic resonance imaging (MRI), allowing for post-operative monitoring without the need for plate removal.

For long bone fractures, such as those in the femur or tibia, titanium plates provide robust fixation that allows for early mobilization. This early return to movement is essential for preventing complications associated with prolonged immobilization, such as muscle atrophy and joint stiffness. The strength of titanium plates also permits weight-bearing sooner than with some other fixation methods, potentially accelerating the overall recovery process.

In spinal surgery, titanium plates are used to stabilize vertebrae and facilitate fusion procedures. The biocompatibility of titanium is particularly beneficial in this delicate area, minimizing the risk of adverse reactions that could compromise the spinal cord or nerve roots. The plates' ability to promote osseointegration also contributes to the long-term success of spinal fusion surgeries.

One of the significant advantages of using titanium plate for bone is their longevity. In many cases, these plates can remain in place indefinitely without causing problems. This eliminates the need for a second surgery to remove the hardware, reducing the overall risk and cost associated with fracture treatment. However, if removal is necessary or desired, the process is typically straightforward due to titanium's resistance to tissue ingrowth.

The use of titanium plates also offers benefits in terms of patient comfort. Their lightweight nature means that patients often report less awareness of the implant compared to plates made from heavier materials. This can contribute to improved quality of life and patient satisfaction following surgery.

Innovations and Future Directions in Titanium Plate Technology

As medical technology continues to advance, so too does the field of titanium plate design and manufacturing. Researchers and engineers are constantly exploring new ways to enhance the performance and biocompatibility of these crucial devices.

One area of active research is surface modification of titanium plates. By altering the surface properties of the plate, scientists aim to further improve osseointegration and reduce the risk of infection. Techniques such as plasma spraying, acid etching, and the application of bioactive coatings are being investigated to create surfaces that more closely mimic natural bone structure and promote faster healing.

Another energizing improvement is the utilize of 3D printing innovation in the generation of titanium plates. This added substance-fabricating approach permits the creation of exceedingly customized plates that impeccably coordinate the patient's life structures. 3D-printed titanium plates can consolidate complex geometries and permeable structures that are troublesome or incomprehensible to accomplish with conventional fabricating strategies. These custom-fitted plans can possibly progress the plate's fit, diminish surgery time, and improve by and large treatment results.

Analysts are moreover investigating the advancement of "shrewd" titanium plate for bone that consolidate sensors to screen the mending handle. These progressed inserts might give real-time information on bone mending, push conveyance, and indeed early signs of contamination. Such data would permit specialists to make more educated choices almost with care and possibly intercede prior if complications emerge.

The integration of titanium plates with other advanced materials is another area of innovation. For example, composite plates that combine titanium with biodegradable polymers are being developed. These hybrid implants could provide initial strength and stability from the titanium component while allowing for gradual transfer of load to the healing bone as the polymer degrades.

As natural concerns develop, the therapeutic gadget industry is too centered on economical homes. Companies like Baoji INT Restorative Titanium Co., Ltd. are contributing to more proficient fabricating forms and investigating ways to reuse and repurpose titanium materials. These endeavors point to diminishing the natural effect of titanium plate generation while keeping up the tall quality and execution benchmarks required for restorative inserts.

The future of titanium plate for bone looks promising, with continuous inquiry and advancement promising to provide indeed more successful and patient-friendly arrangements. As our understanding of bone recuperation and biomaterials proceeds to develop, we can anticipate to see titanium plates that not only are backbreak recuperation but also effectively advance and improve the characteristic mending process.

Conclusion

Titanium plate for bone have revolutionized the treatment of fractures, offering a combination of strength, biocompatibility, and versatility that has made them an indispensable tool in orthopedic surgery. From their ability to provide stable fixation to their promotion of osseointegration, these remarkable devices have significantly improved outcomes for countless patients suffering from bone fractures.

For those interested in learning more about cutting-edge titanium plates for bone and other medical titanium products, Baoji INT Medical Titanium Co., Ltd. stands at the forefront of innovation and quality in this field. With over 30 years of experience in titanium material research, development, and production, INT offers a comprehensive range of medical titanium solutions. To explore their products or discuss your specific needs, don't hesitate to reach out to their team of experts at export@tiint.com.

2025-09-05 15:55:35

2025-09-05 15:55:35

_1753429726760.webp)

_1752644608314.webp)

_1751959047184.webp)

_1750663715751.webp)